Our Fabrication Projects

Home > Projects

We’ll Exceed Your Expectations

Our dedication to delivering tailor-made, cost-effective solutions to meet the needs of our clients is second to none. At Greville Fabrication, we offer outstanding aluminium and steel fabrication services throughout Darwin. We’re immensely proud to have worked on a huge variety of projects over the years, and we’ve produced high-quality products to meet the unique specifications of our clients.

If you have an upcoming project that requires custom fabrication, speak to us at Greville Fabrication today. We’ll be happy to discuss the details over the phone and provide an obligation-free quote. No task is too big or small for our team and we’re confident we can efficiently deliver top-quality steel and aluminium to exceed your expectations.

Tour Trailer

A popular Northern Territory tour company requested a specialised commercial

tour trailer

for their business. Practicality and durability were at the forefront of our design, and the trailer was built to withstand the incredibly harsh conditions of the great Australian outdoors. Our fabricators sourced local materials and the trailer was produced in a matter of weeks. It was inspected by the Territory Government, approved, registered, and will now spend its life on the open road.

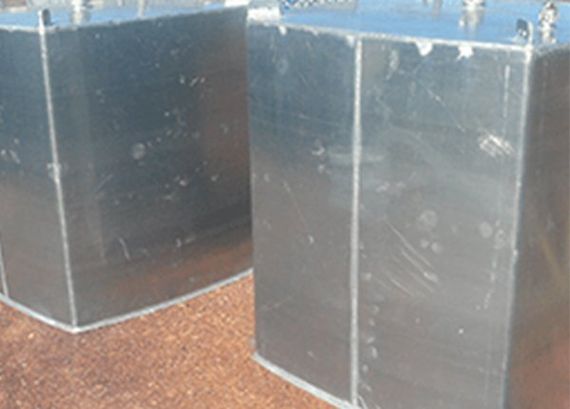

Croc Trap

At Greville Fabrication, we were tasked with the redesign and manufacture of a

crocodile trap for a client in Darwin. There are a number of critical elements to consider when designing a crocodile trap. It needs to be light in weight, easily manoeuvrable, and tough enough to withstand the croc’s onslaught. The safety of our clients is our highest priority, so each trap needs to be fully capable of securely holding saltwater crocodiles weighing up to 1-tonne and measuring 6-metres. This special trap for the Darwin client was built to the highest standard, and we’ve used its design to produce hundreds of other traps for clients throughout the Northern Territory.

Boiler

At Greville Fabrication, we were tasked to re-engineer and manufacture a distilling plant that creates an all-natural bug and insect repellent (as well as a natural healing oil). The plant’s bug spray is widely used across the Leighton’s Index 8000-man site in the Northern Territory. Both steel and stainless steel was used to successfully complete this project.

Barge / Floating Pump Station

At Greville Fabrication, we were given an incredible opportunity to design and manufacture a new floating pump barge for slurry transfer. This barge was constructed entirely out of aluminium and met all Australian marine safety standards. Our team successfully completed the job on time and within budget. The station was fitted out with an operational generator and pump.